SMD Resistor Sorter

August 15, 2022

In the hopes of increasing the efficiency of e-waste recycling, my group of seven students set our sights on engineering an automatic SMD resistor sorter. This proved to be a difficult task, mainly because of just how small SMD resistors can get.

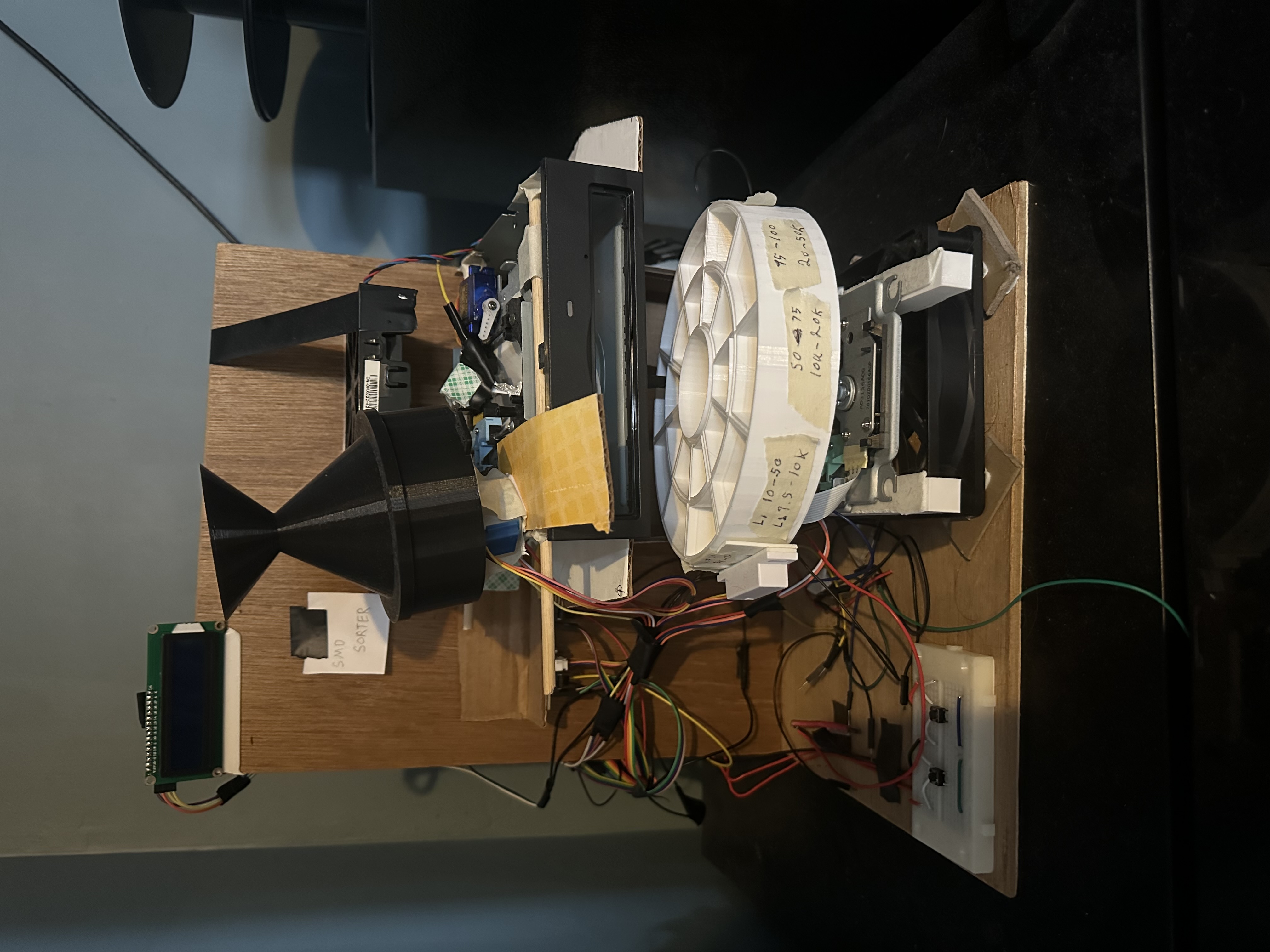

After extensive planning our team got to work, aiming to make our project plans a reality. Along the way, we encountered several issues and obstacles that challenged us and the way we thought about the project. Ultimately, we were able to work together to create an end product that was quite successful. On top of that, we embodied the spirit of our project and its theme (recycling) by almost exclusively using electronics from RPI e-waste.

In the construction of the device we utilized cd drives from old computers to manuever and manipulate the position and orientation of our SMD resistors, we used recovered fans to cool the cd drive stepper motors, and we powered the entire system by utilizing a used 240 watt computer power supply, and we mounted all of these components to scrap wood from the RPI wood shop. All of these supplies working in conjunction with an Arduino Uno delivered an automated system that had the capability to quickly and accurately sort SMD resistors. Unfortunately however, the orientation system we designed failed to reliably place resistors in the measurement ready position. This meant that resistors needed to be manually loaded into the measurement bay to be properly sorted. After much consideration, our group devised several alternative methods to test and eventually implement that may have proved more successful, but ultimately our semester ended before we were able to work on these improvements.

At the end of the day, this project proved quite meaningful to me as an engineer. This was one of the first serious projects I had ever done with a group. Because of this, I was able to learn a lot about teamwork, leadership, and the benefits of working together with other talented engineers. I remain grateful for this experience and will surely draw on the lessons I learned from it for years to come.

My Contributions

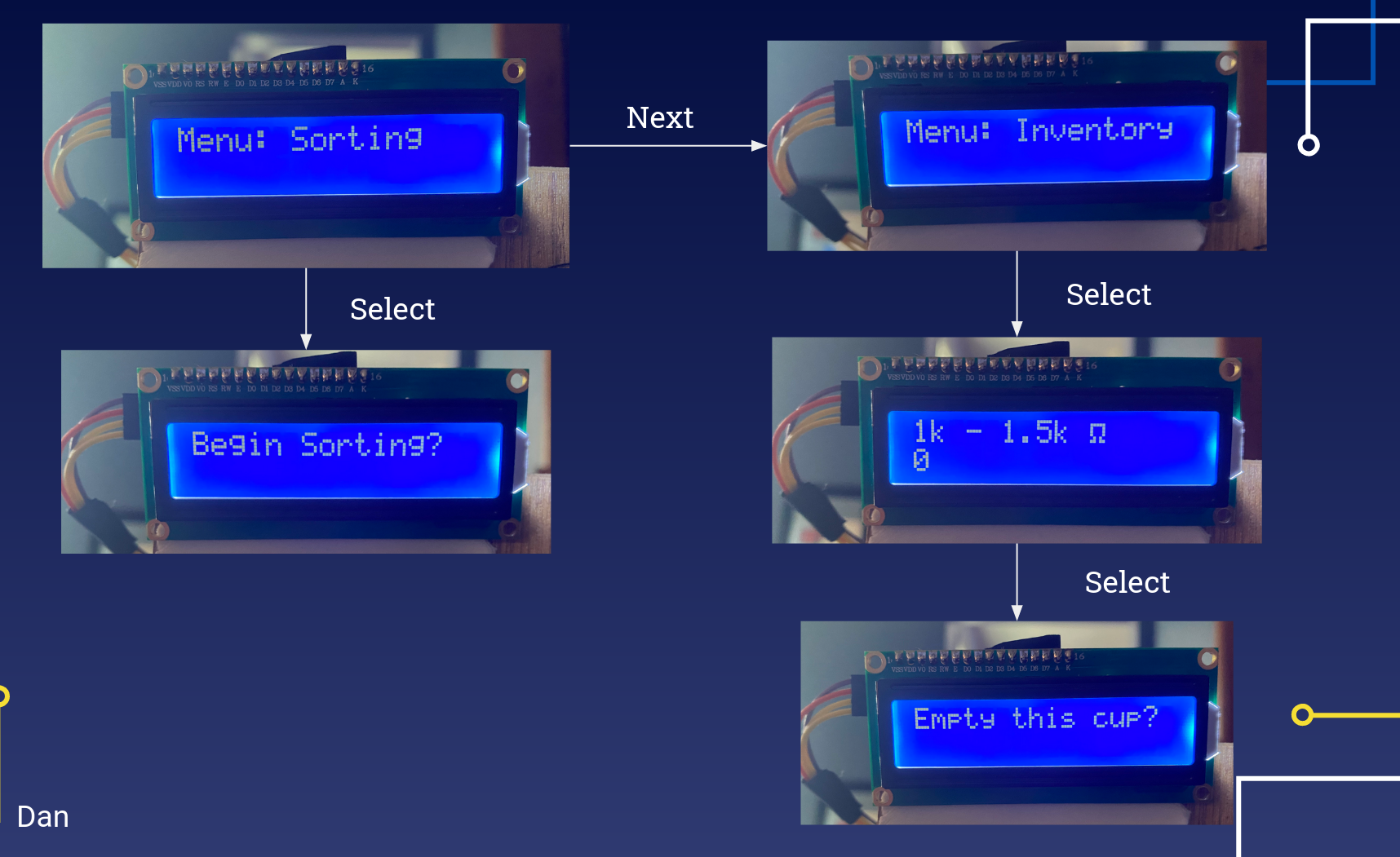

Officially, my duties for this project were to ensure a cohesive user experience. In order to accomplish this I chose to utilize an LCD screen to administer a menu system. The interface was controlled by just two buttons, which allowed us to keep our pin usage on the Arduino to a minimum (this left plenty of room for other connected devices).

The simple menu flow above allowed for easy operation of our sorter while still providing access to complex functions such as removing sorted resistors from the device’s inventory.

After the interface had been fully realized, I transitioned to providing assistance to all other project subsystems. I have a wide range of experience from passion projects I have worked on throughout the years, so I was able to make quite an impact many other subsystems. One of the more significant ways I helped was in the development of the control system. This system was written in the Arduino version of C++ and ended up totaling around 650 lines of code.The system connected all subsystems in the project and ensured that they functioned cohesively and reliably.